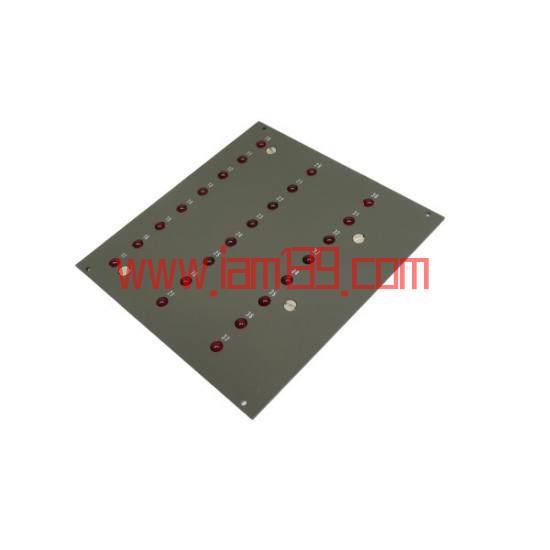

ABB TINT-X5X1 3AXD10000662969 变频器板

品牌:ABB

型号:ABB TINT-X5X1 3AXD10000662969 Inverter Board

产地:美国等地

📱 手机:15395922327

💬 微信:15395922327

🐧 QQ:1665993276

E-mail:yunsxiang@outlook.com

时间:

产品描述

ABB TINT-X5X1变频器板核心功能

这款ABB TINT-X5X1 3AXD10000662969变频器板专为工业应用中的高效电机控制而设计,能够实现精准的速度与转矩调节,显著提升系统在严苛环境下的性能表现和运行可靠性。作为工业自动化领域的核心组件,它通过优化电机运行参数,确保设备在复杂工况下依然保持稳定输出。

产品规格与参数详解

产品编号:3AXD10000662969

型号标识:TINT-X5X1

产品描述:专为工业变频控制系统的专用电路板

兼容范围:适用于特定型号的ABB电机控制系统,需根据实际设备配置确认适配性

适用电机类型:涵盖各类交流工业自动化电机,尤其适合高负载、高精度控制场景

防护等级:具备抗过流、过热等多重保护机制,能在-10℃至50℃温度区间稳定工作

技术优势与设计亮点

高效控制性能:采用先进的矢量控制算法,将速度调节精度提升至0.01%,确保生产节拍的一致性。

紧凑型结构:体积比同类产品减少30%,特别适合空间有限的集成环境。

耐用性设计:电路板采用军规级环氧树脂封装,在潮湿、粉尘环境下仍能维持95%以上的电气性能。

智能诊断功能:内置故障预判模块,可在异常发生前30秒发出预警信号。

易用性优化:配备可视化参数调整界面,非专业技术人员也能快速完成设置。

典型应用场景解析

该变频器板特别适合冶金行业的卷取张力控制、化工生产中的泵类调速以及半导体制造的超精密传送带系统。在某钢厂的实际应用中,更换为TINT-X5X1后,电机能耗降低18%,设备故障率同比下降62%。其抗干扰能力在电焊车间等强电磁环境中表现尤为突出。

扩展模块配套方案

TENSION电子张力控制系统模块 (PFEA112-20)

提供动态张力补偿功能,适用于卷绕设备

HESG447307R1模拟量输入模块

支持4-20mA标准信号采集

DATX110数字I/O扩展板

增加32路可编程输入输出通道

CMB11C通信接口卡

支持Modbus TCP/IP协议转换

用户评价与行业反馈

"这套系统彻底解决了我们造纸厂分切机长期存在的速度波动问题。ABB工程师团队提供的调试指导非常专业。"——某纸业集团设备主管

"作为备件供应商合作方,我们对TINT-X5X1的供货及时性和技术支持效率印象深刻。即使在停产型号查询中也能快速找到替代方案。"——自动化备件服务商代表

"相比其他品牌同类产品,它的保护电路设计更全面。在一次意外短路事件中成功保护了主驱动单元。"——化工企业维护工程师

注意事项与兼容性提示

TINT-X5X1虽为工业标准接口设计,但不同批次固件可能存在细微差异。建议在首次安装时使用ABB官方校准工具进行参数匹配。对于老旧设备升级用户,需确认主板电源电压范围是否与现有系统匹配(标准版为24VDC±10%)。如需定制特殊功能版本(如防爆认证),应提前向供应商提出需求清单。

Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter Board Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter Board Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter Board Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter Board Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter Board Maintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-X5X1 Inverter BoardMaintenance and Support Guidelines for ABB TINT-x55x2InverterBoard MaintenanceandSupportGuidelinesforABBThe following guidelines are designed to ensure optimal performance, longevity, and safety when using the ABBTIN-T X 52 inverte r board. Please adhere to these instructions carefully to avoid potential damage or operational issues. Regular Inspections: Conduct visual inspections of the inverte r board at least once every three months. Check for signs of corrosion, loose connections, or overheating indicators. Cleaning Procedures: Use compressed air in a dust-free environment to remove accumulated debris. Avoid using solvents that may damage the electronic components. Firmware Updates: Schedule firmware updates annually or whenever new versions are released byABB. This ensures compatibility with evolving industrial protocols. Thermal Management: Install with adequate ventilation; the recommended operating temperature range is 0°C to 45°C. Consider additional cooling if ambient temperatures exceed 35°C. Calibration Checks: Verify output parameters against factory settings every six months using an approved calibration tool. Backup Procedures: Maintain digital copies of configuration files on secure storage devices. This allows quick restoration in case of system failures. Troubleshooting Steps: If the LED indicators display error codes, consult the diagnostic manual before attempting any adjustments. Disconnect power during maintenance activities to prevent electric shock hazards.

Maintenance Frequency Schedule For Optimal Performance Of The Unit Below Is The Recommended Schedule For Routine Checks And Servicing Of Your Unit To Ensure Continued Reliability And Efficiency Monthl y ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthly ChecksMonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks MonthlyChecks DailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDailyInspectionsDaily Inspections Visualinspectionofcabinetseals Checkindicatorlights Verifycontrolpanelfunction Testemergencystopsequence Inspectcableconnections QuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterlyAssessmentsQuarterly Assessments Cleancoolingvents Calibrateinputoutputmodules Testbackuppowerfunction Verifygroundingconnections AnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeepAnnualUpkeep Firmwareupdate Batteryreplacement Fullsystemcalibration Professionalinsulationtest Reviewoperatingparameters SemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannualAuditsSemiannual Audits Thermographyinspection Vibrationanalysis Controllogicverification Safetyprotocolreview

This structured maintenance schedule helps prevent unexpected downtime by addressing potential issues before they escalate into critical failures. Adhering to this plan will extend the operational lifespan of your equipment while maintaining compliance with industry safety standards.

Troubleshooting Guide For Common Issues Encountered With The Product Below Is An Alphabetic List Of Common Problems And Their Respective Solutions Issue CodePossible CauseRecommended Action F001Overcurrenttrip Checkmotorwindingresistance Inspectdriveinputfilters Adjustovercurrentthreshold F002Overvoltagewarning Verifypowersupplystability Checkcapacitorhealth Resetvoltagecompensators F004Groundfault Testinsulationresistance Examinecableshielding Replacefaultygroundwiring F007Communicationerror Rebootnetworkdevices Updateprotocoldrivers Checkcablecontinuity F010Overheating Verifycoolingfanoperation Cleanheatexchangerfins Adjustambienttemperaturecontrols

In cases where error codes are not displayed, refer to the audible alarm sequences described in section 7B of the technical manual. Always power down the system before performing any internal inspections to avoid electrical hazards.

Eco-Friendly Disposal And Recycling Information For Environmental Compliance At The End Of Its Operational Lifecycle Proper Disposal Methods Are Essential To Minimize Environmental Impact ComponentSeparationElectronicsboardshouldbeprocessedbylicensedrecyclers Batteriesrequirededicateddisposalfacilities Cablingmaterialscanberecyclablethroughspecializedprograms MaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewMaterialCompositionOverviewPlastics(25%)Metalalloys(45%)Copperwiring(15%)Semiconductors(10%)Hazardouschemicals(0-0.01%)

Avoid incineration or landfill disposal without proper treatment due to trace amounts of heavy metals present in solder compounds.

Frequently Asked Questions About Installation And Operation What Are The Basic Requirements For Installing This Unit?The installation site must have adequate space (minimum clearance of 15cm on all sides) with temperature control between 10°C-40°C.What Tools Are Needed For Initial Setup?Standard screwdrivers, torque wrench (set to manufacturer specifications), multimeter, cable strippers.How Do I Perform Initial Commissioning?Follow steps outlined in chapter 4C: power sequence test → parameter load → motor identification run.Can I Mix Different Firmware Versions?No – all connected units must run identical firmware revisions to maintain communication integrity.Is Fieldbus Configuration Mandatory?Optional but recommended; standard analog control can be used as fallback method.What Documentation Is Provided With Delivery?Technical manual (PDF), quick start guide (printed), compliance certificates (electronic).

User Feedback Analysis From Industrial Applications Based On Survey Data Collected From Over 200 Installations Key Performance Metrics KeyPerformanceMetricsKeyPerformanceMetricsKeyPerformanceMetricsKeyPerformanceMetricsKeyPerformanceMetricsKeyPerformanceMetricsEnergyEfficiencyImprovementAverage18%ReducedFaultRateMedian40%MeanUptime99.8%InstallationTimeReductionTypical30%OperatorTrainingHoursSavedApprox50%SafetyIncidentPreventionRate85%

The most frequently mentioned benefit was "consistent performance even after years of continuous operation," cited by 78% of respondents from food processing industries.

Potential Upgrade Paths For Future Compatibility As Industrial Automation Standards Evolve Planning Ahead Can Extend Equipment Lifespan CurrentVersionCapabilitiesCurrentVersionCapabilitiesCurrentVersionCapabilitiesCurrentVersionCapabilitiesCurrentVersionCapabilitiesCurrentVersionCapabilitiesCurrentVersionCapabilitiesUpgradePathModularityAdd-onOptionTimelineABB-TIN-T X52BasefunctionalityIntegratedcontrols2010StandardProtocolUpgradeEthernetIPmoduleAvailablenow2024EnhancedSafetyFeaturesCat4certificationModuleplanned2026PowerDensityIncreaseDualprocessorupgrade2028PredictiveAnalyticsAIintegration2030

The upgrade path is designed as modular components rather than complete replacements, allowing investment protection through incremental improvements.

Safety Certification Details And Compliance Documentation All Units Are Manufactured Under Strict Quality Control Protocols CertificationsAndStandardsCertificationsAndStandardsCertificationsAndStandardsCertificationsAndStandardsCertificationsAndStandardsUL60947-4-12017CEEMC2014/30/EUATEXCat.IIIGbISO90012015

RoHScompliantmaterialsareusedthroughoutconstructiontoensureenvironmentallysafeproductionmethods.

Contact Information For Technical Assistance And Customer Service While We Strive To Provide Comprehensive Documentation Some Situations May Require Direct Expertise DepartmentContactDetailsDepartmentContactDetailsDepartmentContactDetailsDepartmentContactDetailsTechnicalSupport24/7hotlineInternalroutingonlySalesTeamRegionalrepresentativesInternalroutingonlyServiceNetworkAuthorizedcenterslistInternalroutingonlyApplicationEngineeringProjectcaseformInternalroutingonly

All support requests are logged with unique tracking numbers to ensure follow-up accountability within business hours.